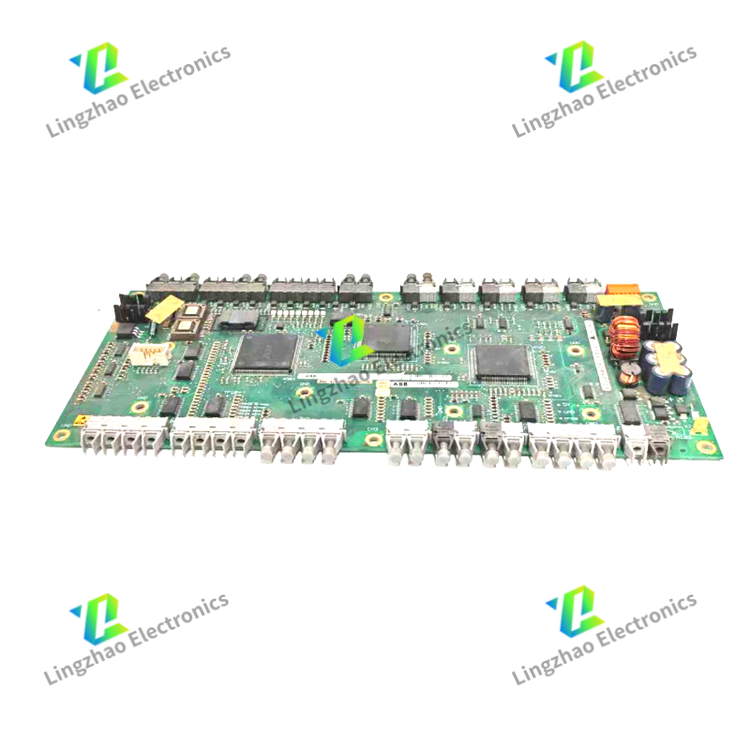

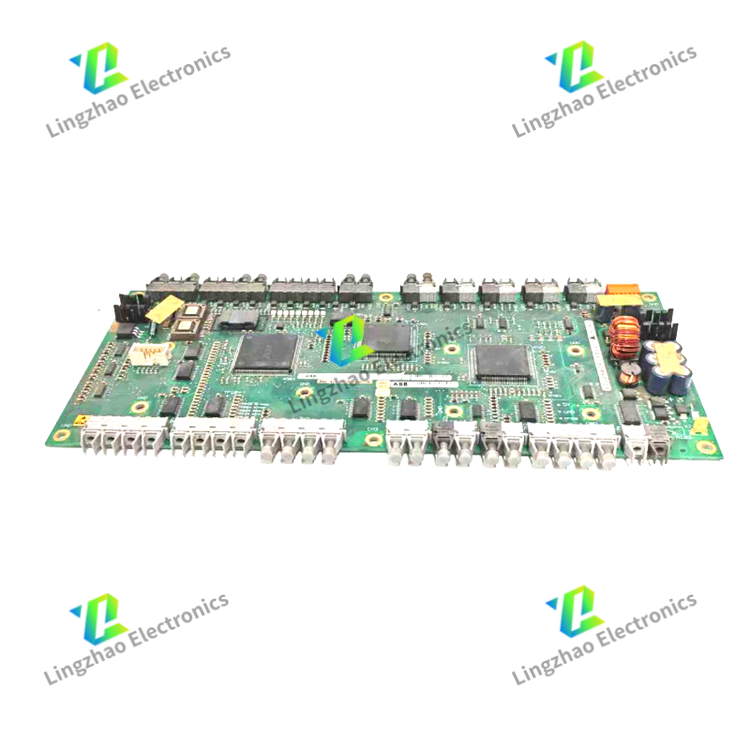

PPC902AE101 3BHE010751R0101 reliable mid-range Power Process Control Unit

PPC902AE101 (with 3BHE010751R0101 as its exclusive order number) is a reliable mid-range Power Process Control Unit developed by ABB, tailored for medium-voltage power conversion systems and industrial process control scenarios. It integrates real-time control, multi-channel signal acquisition, and standardized communication functions, serving as a core control module for equipment like industrial drives, inverters, and power quality devices—balancing performance, cost-effectiveness, and ease of integration. The detailed information is as follows:

| Package Type | Rugged industrial panel/rack-mounted enclosure (19-inch standard rack, 1U height; metal housing with anti-corrosion coating and basic EMC shielding; front-panel LEDs for power, communication, and fault status visualization) |

| Weight | Approximately 1.8–2.5 kg (varies by accessory kits, including mounting brackets, terminal covers, and wiring labels) |

| Key Compatibility | Optimized for ABB’s mid-power medium-voltage product lines, including ACS880 MV series industrial drives (100kW–2MW), small-to-medium renewable energy converters (e.g., 50kW–500kW solar inverters), and low-voltage SVG (Static Var Generator) systems, ensuring seamless hardware-software collaboration. |

- Input Voltage: Single 24VDC ±10% (for control circuits and internal components); optional redundant 24VDC input (via add-on module) for critical applications requiring high availability.

- Power Consumption: Typical 12W (normal operation), maximum 25W (full-load with all I/O and communication active).

- Isolation Performance:

- Between power input and signal circuits: ≥2500V AC (1 minute, IEC 60664-1 standard), preventing electrical interference and ensuring operator safety;

- Between analog input channels: ≥1000V AC (1 minute), reducing cross-talk between monitoring signals.

- Microprocessor: Equipped with a 32-bit industrial-grade MCU (clock frequency ≥150MHz) optimized for real-time control, supporting a minimum control cycle of 200μs (sufficient for mid-power systems’ dynamic response needs, e.g., motor speed regulation, inverter voltage control).

- Memory Configuration:

- Flash memory: 4MB (for program storage, parameter backup, and system firmware);

- RAM: 256KB (for real-time data processing and algorithm execution);

- Non-volatile memory (NVM): 128KB (for storing up to 50 historical fault records, including time stamps and pre-fault operating parameters).

- Analog/Digital I/O (Input/Output):

- Analog Input (AI): 6 channels (4–20mA or 0–10V, 12-bit resolution), used for monitoring critical parameters (e.g., DC bus voltage, output current, IGBT junction temperature, ambient temperature).

- Analog Output (AO): 2 channels (4–20mA, 12-bit resolution), for controlling external devices (e.g., variable-speed cooling fans, voltage regulators).

- Digital Input (DI): 12 channels (24VDC level, with 1ms debounce filtering), for receiving status signals (e.g., "drive enable," "grid contactor closed," "emergency stop," "fault reset").

- Digital Output (DO): 6 channels (relay contacts: 250V AC/30V DC, 3A; open-collector: 24V DC, 1A), for driving alarms, indicator lights, or low-power contactors.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

PPC902AE101 3BHE010751R0101

Product

Product ABB

ABB