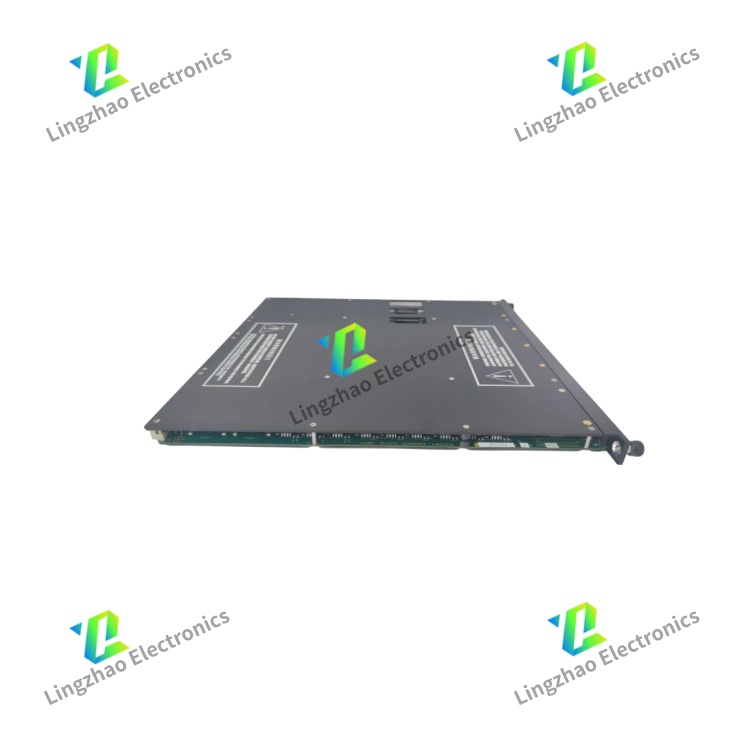

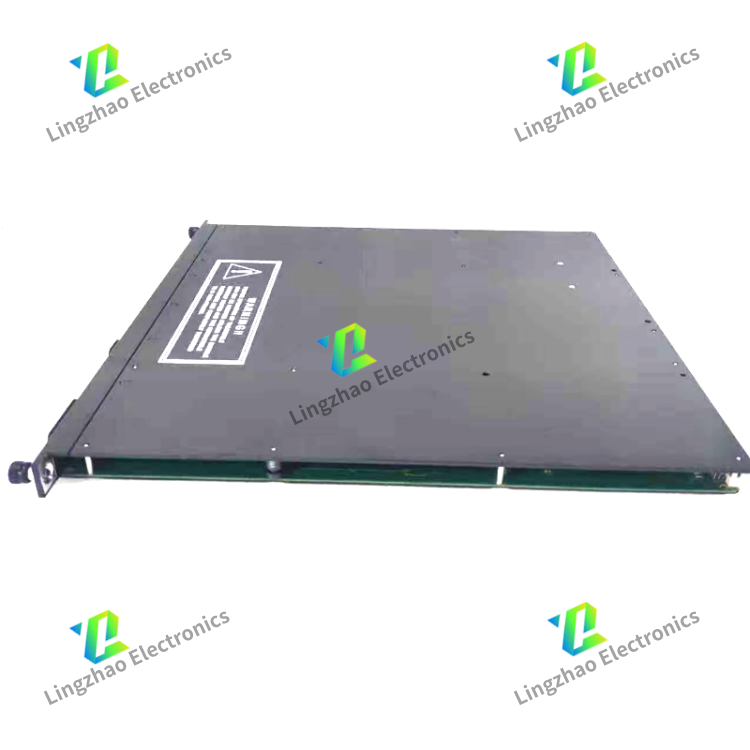

TRICONEX 2381 analog input module

The TRICONEX 2381 is a high-performance analog input module designed for Triconex Safety Instrumented Systems (SIS) and critical process control applications. As a key component in Triconex’s fault-tolerant product lineup, it specializes in accurately acquiring, conditioning, and transmitting continuous analog signals from field sensors (e.g., temperature, pressure, flow transmitters) to Triconex controllers. It is engineered to meet strict safety and reliability standards, making it ideal for safety-critical scenarios where precise, uninterrupted signal acquisition is essential. Below is its comprehensive detailed information:

The primary role of the TRICONEX 2381 is to serve as a "precision analog signal bridge" between field instruments and Triconex controllers. Its core functions include:

- Analog Signal Acquisition: Receiving standard industrial analog signals (e.g., 4–20mA DC current signals, 0–10V DC voltage signals) from field sensors (e.g., pressure transmitters, RTD temperature sensors, flow meters).

- Signal Conditioning: Filtering noise, stabilizing voltage/current levels, and linearizing non-standard signals to ensure the accuracy of raw data before conversion.

- Digital Conversion: Converting conditioned analog signals into high-resolution digital data via a built-in ADC (Analog-to-Digital Converter), which is then transmitted to Triconex controllers for safety logic calculation, process monitoring, or closed-loop control.

- Safety Support: Integrating with Triconex’s Triple Modular Redundancy (TMR) architecture to ensure fault tolerance, enabling continuous operation even if partial components fail—critical for maintaining safety in processes like emergency shutdown (ESD) or reactor protection.

- Input Signal Type: Configurable to support multiple standard industrial analog signals (via software or hardware jumpers):

- Current input: 4–20mA DC (two-wire/three-wire transmitter compatible, common for pressure/flow sensors).

- Voltage input: 0–5V DC, 0–10V DC (for sensors like level transmitters or pH meters).

- RTD input (optional variant): Supports Pt100/Pt1000 platinum resistance thermometers (for high-precision temperature measurement, e.g., turbine bearing temperature).

- Input Channel Count: 16 independent analog input channels (group-isolated, typically 4 channels per isolation group to reduce cross-interference).

- Resolution: 16-bit ADC (ensures detection of small signal variations, e.g., 0.006mA increments for 4–20mA signals).

- Measurement Accuracy:

- Current/voltage input: ±0.1% of full scale (FS) (at 25°C, room temperature), ±0.2% FS (over operating temperature range: -40°C to +70°C).

- RTD input (if applicable): ±0.1°C (for Pt100, -200°C to +600°C range), meeting high-precision temperature monitoring needs.

- Input Impedance:

- Current input: <100Ω (avoids affecting transmitter output stability).

- Voltage input: >1MΩ (minimizes signal attenuation during transmission).

- RTD input: <10Ω (reduces measurement errors caused by lead resistance).

- Power Supply: +5V DC (supplied by Triconex system backplane), typical power consumption <4W (excluding external sensor power).

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

Product

Product Triconex

Triconex

Online Consultation

Online Consultation 13328303947

13328303947