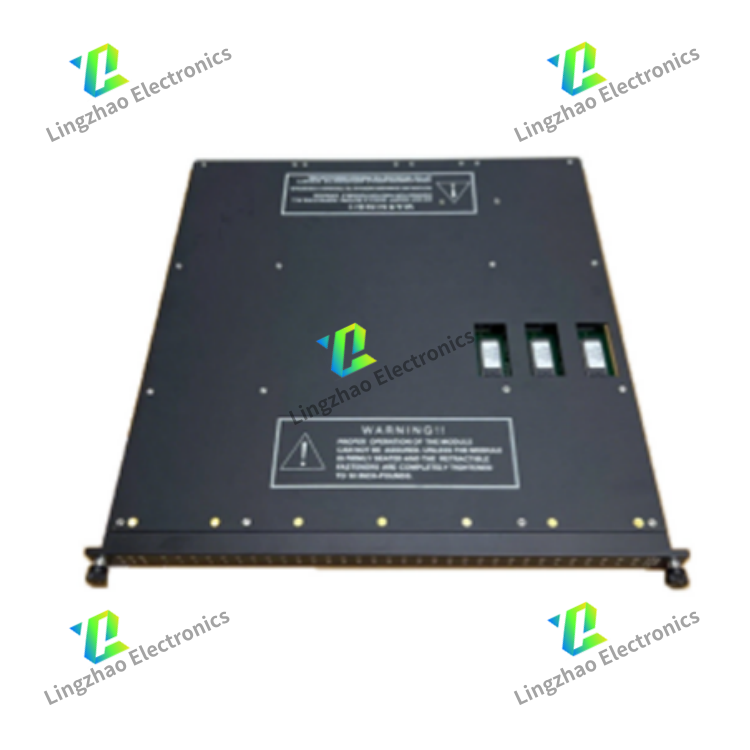

TRICONEX 3301 analog input (AI) safety module

The TRICONEX 3301 is an analog input (AI) safety module launched by Triconex, a brand under Rockwell Automation. Specifically designed for Triconex Triple Modular Redundancy (TMR) safety control systems, it is primarily used to collect safety-related analog signals (such as pressure, temperature, liquid level, and other continuous variables) from industrial sites. It provides accurate and reliable data sources for the interlock logic calculation of Safety Instrumented Systems (SIS) and is suitable for high-risk industries like petroleum, chemical engineering, and electric power. The following is its detailed information:

TMR Redundant Architecture and Safety Level

- Adopts the Triple Modular Redundancy (TMR) design consistent with Triconex safety systems. Three independent signal acquisition channels process the same analog signal in parallel, and verify data validity through a 2-out-of-3 (2oo3) voting mechanism. Even if a single channel fails (e.g., amplifier drift, line interference), it can still ensure the accuracy of signal acquisition, avoiding false or missed actions of safety interlocks caused by data errors.

- Meets the world’s highest safety standards: TÜV-certified SIL 3 (Safety Integrity Level 3), compliant with IEC 61508 (general safety standard) and IEC 61511 (process industry safety standard). It is suitable for critical safety loops (e.g., reactor overpressure monitoring, tank high-level interlock).

Multi-Type Signal Acquisition Capability

- Supports common industrial analog input types and can directly collect signals without additional hardware conversion:

- Current signals: 4-20mA DC (2-wire/4-wire, compatible with on-site transmitters);

- Voltage signals: 0-10V DC (suitable for signals output by sensors or controllers);

- Thermocouple/RTD signals (for some models): Such as K-type, J-type thermocouples, and PT100 RTDs. It can directly collect temperature signals, reducing errors in intermediate conversion links.

- Equipped with programmable signal range function. The measurement range of each channel (e.g., 4-20mA corresponding to 0-10MPa pressure) can be flexibly configured via software, adapting to on-site equipment with different ranges and reducing the complexity of module selection.

High Precision and Anti-Interference Design

- Adopts high-precision signal conditioning circuits (e.g., 16-bit or higher resolution ADC). The analog acquisition error is usually less than ±0.1% FS (full scale), ensuring accurate capture of small signal changes (e.g., slight pressure fluctuations) and meeting the strict requirements of safety interlocks for data precision.

- Electrical isolation (isolation voltage ≥2500V AC) is applied between channels, and between the module and the backplane. Combined with filter circuits (e.g., anti-EMI filters), it can effectively suppress electromagnetic interference (EMI) and ground loop interference in industrial sites, avoiding signal distortion.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

Product

Product Triconex

Triconex

Online Consultation

Online Consultation 13328303947

13328303947