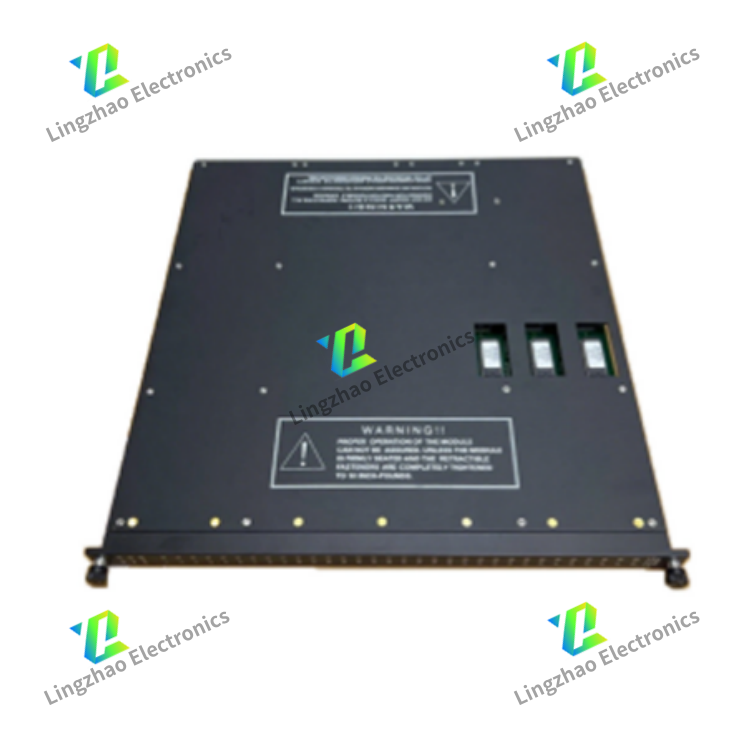

PM864AK01-eA 3BSE018161R2 Enhanced redundant controller module

PM864AK01-eA (order number: 3BSE018161R2) is an enhanced redundant controller module in ABB's AC 800M series, serving as an upgraded version of PM864AK01. It is mainly designed for high-reliability control requirements of medium to large-scale industrial automation systems, with optimizations in redundancy performance, compatibility, and adaptability to industrial environments. Here is its detailed information:

- Module Type: AC 800M series medium-sized enhanced redundant main controller

- Processor: Equipped with a high-performance 32-bit processor with improved computing capability compared to the basic version, supporting complex control algorithms (such as multivariable PID, sequential control, batch control, etc.) and large-scale logical operations

- Memory Configuration:

- Program Memory (RAM): Typical 128MB, supporting stable operation of medium to large-scale control programs

- Data Storage (Flash): Typical 64MB, capable of persistently storing programs, configuration files, and critical process data without loss during power failure

- Communication Interfaces:

- 1 Ethernet interface (10/100 Mbps), supporting industrial protocols such as TCP/IP, Modbus TCP, and OPC for connecting to HMI, SCADA systems, or enterprise-level networks with enhanced communication stability

- 1 ModuleBus interface for high-speed connection with S800 I/O series modules, enabling rapid acquisition of on-site signals and issuance of control commands

- Supports redundant communication architecture with configurable dual network ports to enhance anti-interference capability and reliability of data transmission

- Redundancy Function: Supports hot-standby redundant configuration (requires matching redundant racks and power modules) with an active-standby controller switchover time ≤ 10ms, ensuring uninterrupted operation of critical production processes with disturbance-free switching

- Operating Voltage: 24V DC (±10%) with stronger voltage adaptability to cope with voltage fluctuations in industrial sites

- Power Consumption: Typical 12W, maximum 14W, with slightly optimized energy efficiency compared to the basic version

- Operating Temperature Range: -10°C to +60°C (extended wide temperature range, adapting to harsher environments)

- Storage Temperature Range: -40°C to +85°C

- Enhanced Redundancy Reliability: Based on the redundancy design of the basic version, it optimizes fault detection and switching mechanisms, supporting full redundancy monitoring of controllers, power supplies, and communication links. The system's Mean Time Between Failures (MTBF) is further improved, making it suitable for industrial scenarios with extremely high continuity requirements.

- Improved Compatibility and Expandability: It is not only compatible with all I/O modules in the AC 800M series but also enhances communication compatibility with third-party devices (such as intelligent instruments, sensors, actuators), supporting more industrial protocols to facilitate system integration and expansion.

- Strengthened Adaptability to Industrial Environments: It has passed stricter Electromagnetic Compatibility (EMC) certifications with improved vibration and shock resistance, enabling stable operation in harsh industrial environments with high dust and humidity levels.

- Flexible Programming and Diagnostics: Compatible with ABB Control Builder M programming software, supporting IEC 61131-3 standard programming languages, and providing richer diagnostic functions. It can real-time monitor parameters such as module temperature, power status, and communication quality, with fault information fed back in real-time through the bus or network for quick troubleshooting.

- Convenient Maintenance: Supports online programming, parameter modification, and hot swapping, ensuring maintenance processes do not affect system operation and reducing downtime costs.

- Mainly used for core control in medium to large-scale industrial automation systems, such as process control and equipment management in scenarios like petrochemical complex plants, large metallurgical production lines, urban central heating systems, and medium-sized power stations.

- Particularly suitable for critical process links with high requirements for system reliability and environmental adaptability, such as chemical reactor control, metallurgical rolling mill automation, and energy station load regulation, providing a stable control core for the safe and efficient operation of production processes.

With its enhanced redundancy performance, wider compatibility, and better environmental adaptability, PM864AK01-eA has become an ideal choice balancing stability and expandability in medium to large-scale industrial automation systems, especially suitable for continuous production scenarios in complex industrial environments.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

PM864A 3BSE018162R1

PM825 3BSE010796R1

PM866A 3BSE076359

PM864AK01 3BSE018161R

PM866K01 3BSE050198R1

PM891K01 3BSE053241R1

Product

Product ABB

ABB

Online Consultation

Online Consultation 13328303947

13328303947