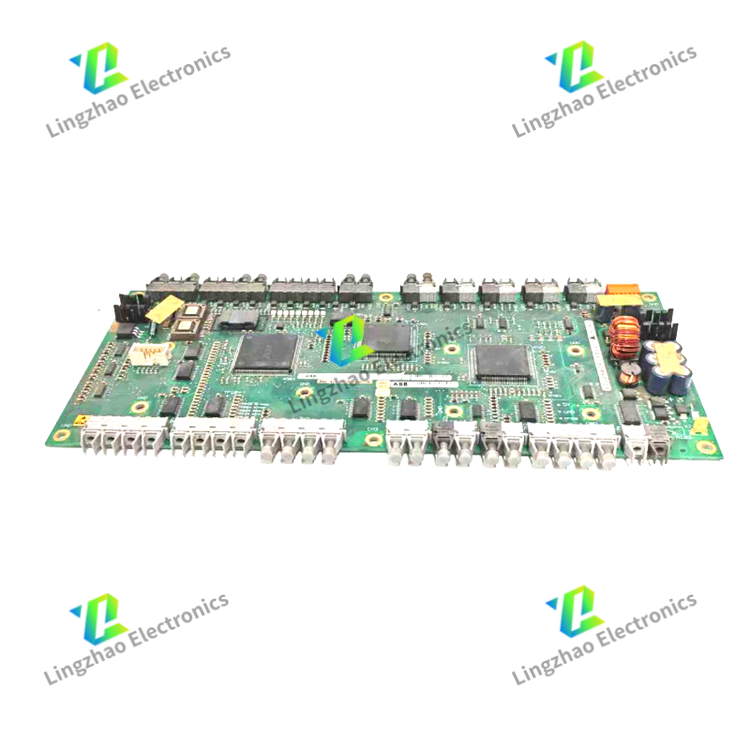

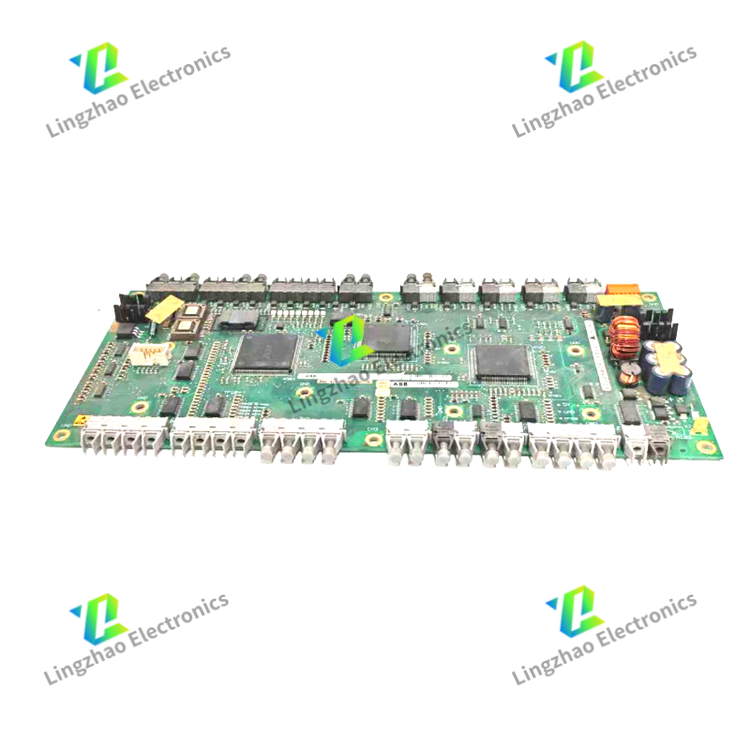

PPC380AE102 HIEE300885R0102 cost-effective, compact Power Process Control Unit

PPC380AE102 (with HIEE300885R0102 as its exclusive order number) is a cost-effective, compact Power Process Control Unit developed by ABB, specifically designed for low-to-medium voltage power conversion systems and small-scale industrial control scenarios. It integrates basic real-time control, simplified signal acquisition, and standardized communication functions, serving as a reliable control core for entry-level industrial drives, small inverters, and auxiliary power equipment—balancing functionality, ease of use, and economic efficiency. The detailed information is as follows:

- Input Voltage: Single 24VDC ±10% (for control circuits and internal components; no redundant input by default, but supports external redundant power connection via auxiliary terminals for optional high-availability needs).

- Power Consumption: Typical 8W (normal operation), maximum 15W (full-load with all I/O and communication active).

- Isolation Performance:

- Between power input and signal circuits: ≥2000V AC (1 minute, IEC 60664-1 standard), preventing electrical interference and ensuring operator safety;

- Between analog input channels: ≥800V AC (1 minute), reducing cross-talk for basic monitoring signals.

- Microprocessor: Equipped with a 32-bit industrial-grade MCU (clock frequency ≥100MHz) optimized for low-power control scenarios, supporting a minimum control cycle of 500μs (sufficient for entry-level systems’ dynamic needs, e.g., small motor speed regulation, auxiliary inverter voltage control).

- Memory Configuration:

- Flash memory: 2MB (for program storage, system firmware, and parameter backup);

- RAM: 128KB (for real-time data processing and basic algorithm execution);

- Non-volatile memory (NVM): 64KB (for storing up to 30 historical fault records, including time stamps and key pre-fault parameters).

- Analog/Digital I/O (Input/Output):

- Analog Input (AI): 4 channels (4–20mA or 0–10V, 10-bit resolution), used for monitoring core parameters (e.g., output current, DC bus voltage, ambient temperature).

- Analog Output (AO): 2 channels (4–20mA, 10-bit resolution), for controlling external low-power devices (e.g., small cooling fans, indicator lamps).

- Digital Input (DI): 8 channels (24VDC level, with 2ms debounce filtering), for receiving basic status signals (e.g., "start/stop," "drive enable," "emergency stop," "fault reset").

- Digital Output (DO): 4 channels (open-collector: 24V DC, 1A; no relay contacts by default), for driving low-power alarms or auxiliary switches.

- Built-in Simplified Algorithms: Integrates ABB’s mature entry-level control logic, tailored for small-power systems:

- Voltage-Frequency (V/F) Control: Ensures stable speed regulation for induction motors in light-load applications (e.g., fans, pumps), with speed accuracy ≤2% of rated speed.

- Basic PWM Generation: Optimizes inverter output for low harmonic distortion (THD <8% for balanced loads), suitable for non-critical industrial processes.

- Load Adaptation: Automatically adjusts output voltage/current based on minor load changes (e.g., fan air resistance fluctuations), avoiding system overload.

- User-Friendly Parameter Setting: Supports basic parameter adjustment via external HMI (via RS485) or ABB’s lightweight configuration software (e.g., Drive Composer Lite), with preset application templates (e.g., "pump mode," "fan mode") to reduce setup time.

- Simplified Parameter Tracking: Continuously monitors 20+ key operating parameters (e.g., input voltage, output current, internal temperature) and transmits data to upper-level devices via communication; triggers visual alarms (front-panel LEDs) for abnormal values (e.g., overtemperature, undervoltage).

- Basic Fault Handling:

- Detects common faults: Overcurrent, overvoltage, overtemperature, undervoltage, and communication loss;

- Protective Actions: Shuts down the system within ≤5ms for critical faults (e.g., short circuit) to prevent equipment damage; activates alarm for minor faults (e.g., low input voltage) without immediate shutdown.

- Fault Troubleshooting: Provides simple fault codes (via LEDs or HMI) for quick identification (e.g., "Fault 01: Overcurrent," "Fault 02: Overtemperature").

- Basic Industrial Protocols: Focuses on cost-effective, widely used communication interfaces for small-scale networks:

- RS485 Interface: 1 channel (supports Modbus RTU, baud rate up to 9600 bps), for local communication with HMIs, small PLCs, or data loggers—sufficient for low-data-volume scenarios (e.g., parameter reading, status monitoring).

- No Ethernet by Default: Optional Ethernet module (add-on) available for users needing remote monitoring (e.g., building automation systems), but not included in the base model to control cost.

- ABB Compatibility: Seamlessly communicates with ABB’s entry-level drives (e.g., ACS580) and HMIs (e.g., ABB CP600), supporting plug-and-play integration without custom protocol development.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

Product

Product ABB

ABB

Online Consultation

Online Consultation 13328303947

13328303947