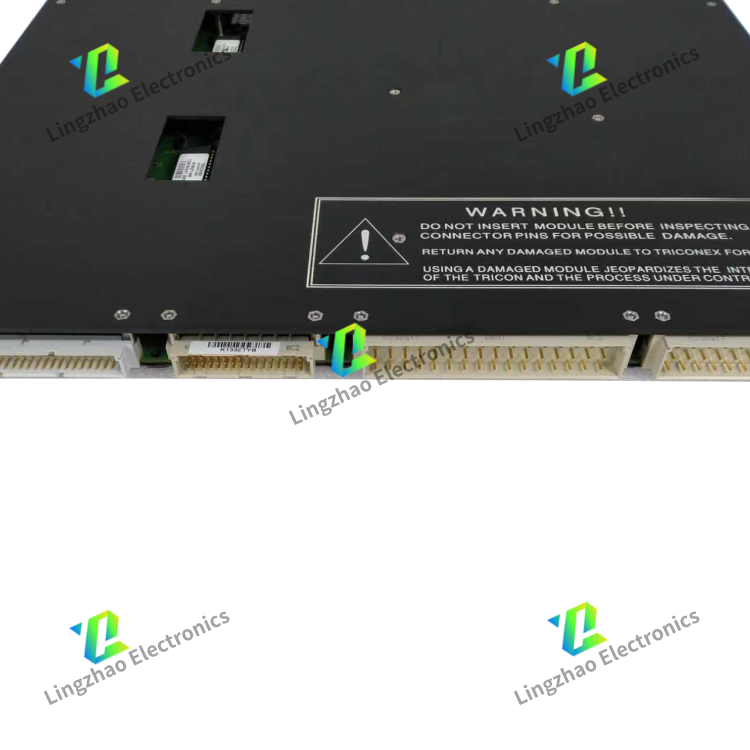

TRICONEX 4201 digital output (DO) safety module

The TRICONEX 4201 is a digital output (DO) safety module developed by Triconex, a brand under Rockwell Automation. It is specifically designed for Triconex Triple Modular Redundancy (TMR) safety control systems, primarily used to output safety-related digital signals to on-site executive devices (such as solenoid valves, contactors, alarm lights, etc.). It ensures reliable execution of safety interlock actions (e.g., emergency shutdown, valve closing) in high-risk industrial environments, and is a core component of Safety Instrumented Systems (SIS). Below is its detailed information:

TMR Redundancy & Safety Level Compliance

- Adopts the same Triple Modular Redundancy (TMR) architecture as the Triconex safety system. Three independent output channels process and verify control signals in parallel, and implement a 2-out-of-3 (2oo3) voting mechanism. This design can automatically shield single-channel faults (such as component damage, signal distortion) to avoid incorrect output actions caused by module failures.

- Fully complies with international safety standards: Certified SIL 3 (Safety Integrity Level 3) by TÜV, and meets IEC 61508 (general safety standard) and IEC 61511 (process industry safety standard). It is suitable for critical safety loops that require "zero false action" and "zero miss action" (e.g., emergency shutdown of chemical reactors, fire protection system activation).

Dual-Channel Output & Force-Guided Relay Design

- Most models are equipped with dual-channel independent output per point. For example, each output point uses two force-guided (positive-guided) relays. When the safety controller issues an action command, the two relays act simultaneously to drive the executive device; if one relay fails (e.g., stuck), the other can still ensure the action is executed, further reducing the risk of output failure.

- The force-guided relay has mechanical interlocking characteristics. It can physically prevent the relay from being in an "ambiguous state" (e.g., both contacts open and closed), and feed back the actual contact state to the controller through a status monitoring circuit, enabling real-time verification of "command issuance - action execution" consistency.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

Product

Product Triconex

Triconex

Online Consultation

Online Consultation 13328303947

13328303947