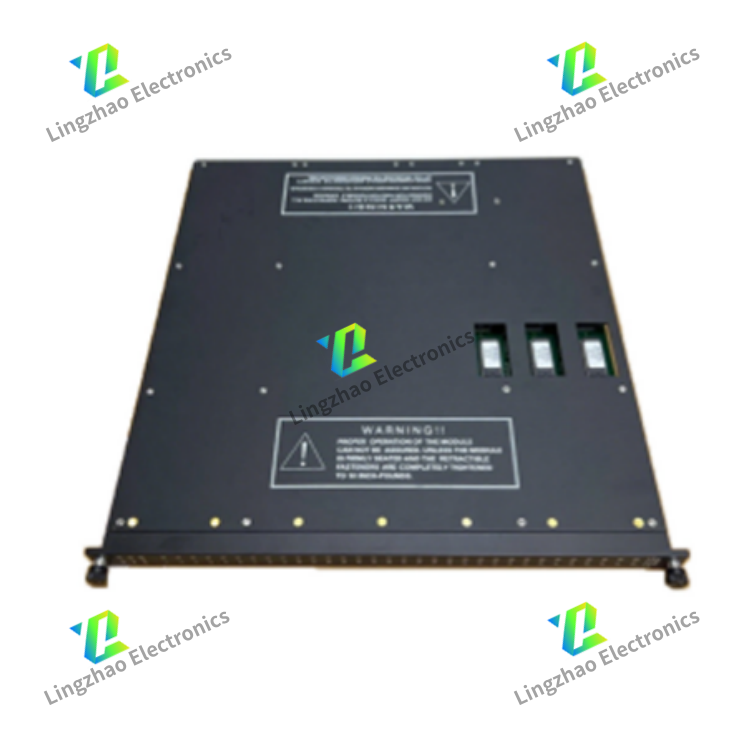

TRICONEX AO2481 safety-grade analog output (AO) module

The TRICONEX AO2481 is a safety-grade analog output (AO) module developed by Triconex (a brand under Rockwell Automation), specifically designed for Triconex Triple Modular Redundancy (TMR) safety control systems. It is mainly used to convert digital control signals from safety controllers into continuous analog output signals (e.g., current or voltage) to drive on-site executive devices such as control valves, variable frequency drives (VFDs), and analog regulators. It ensures accurate and reliable execution of safety-related control actions in high-risk industrial environments, and is a core component of Safety Instrumented Systems (SIS). Below is its detailed information:

TMR Redundancy & SIL 3 Safety Compliance

- Adopts the same Triple Modular Redundancy (TMR) architecture as the Triconex safety system. Three independent output channels process the same digital control signal in parallel, and implement a 2-out-of-3 (2oo3) voting mechanism. This design automatically shields single-channel faults (e.g., DAC drift, circuit failure) to avoid incorrect analog output values, ensuring the safety and stability of executive devices.

- Fully complies with international safety standards: TÜV-certified SIL 3 (Safety Integrity Level 3), meeting IEC 61508 (general safety standard) and IEC 61511 (process industry safety standard). It is suitable for critical control loops that require high precision and fault tolerance (e.g., reactor pressure regulation, pipeline flow control).

Multi-Type Analog Output Support

- Supports mainstream industrial analog output signals, adapting to different types of on-site executive devices without additional signal conversion hardware:

- Current output: 4–20mA DC (the most common type, suitable for long-distance transmission, anti-interference, and driving control valves or transmitters).

- Voltage output: 0–10V DC (for short-distance transmission, suitable for driving VFDs or small analog regulators).

- Each output channel supports programmable range adjustment (e.g., setting 4–20mA to correspond to 0–10MPa pressure control range). The range can be configured via upper-level software, flexibly matching the rated input range of on-site devices.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

Product

Product Triconex

Triconex

Online Consultation

Online Consultation 13328303947

13328303947