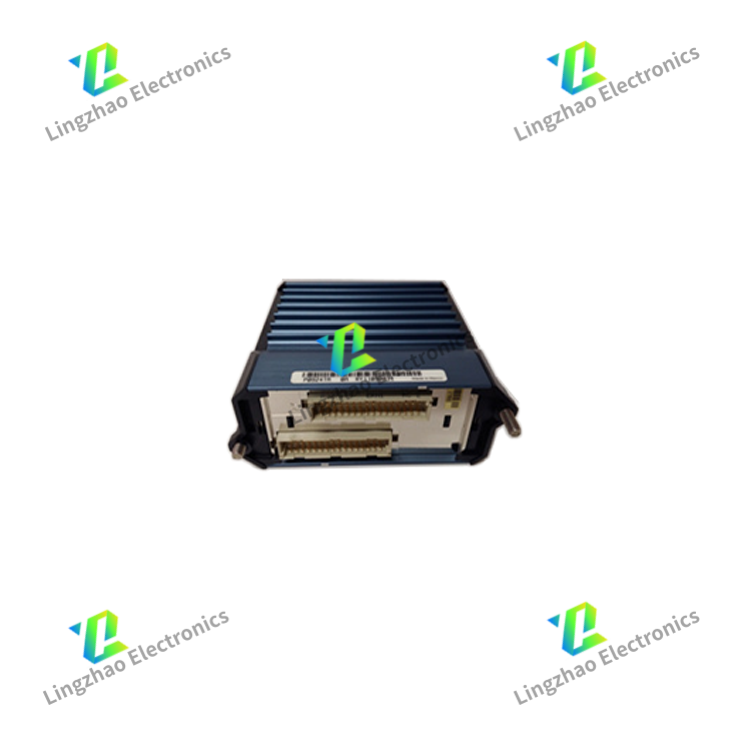

3500/40 176449-01 dual-channel velocity and vibration monitor module

BENTLY 3500/40 (with part number 176449-01) is a dual-channel velocity and vibration monitor module developed by Bently Nevada, specifically designed for the 3500 Series Machinery Protection System. It is tailored to monitor velocity-based vibration (e.g., bearing housing vibration) and acceleration signals of rotating machinery (such as motors, pumps, fans, and small turbines), providing real-time fault alerts and protection actions to prevent mechanical failures. As a core monitoring component in mid-to-low speed rotating equipment applications, it integrates high-precision signal processing, flexible alarm configuration, and seamless integration with the 3500 system, ensuring reliable operation in industrial environments. The detailed information is as follows:

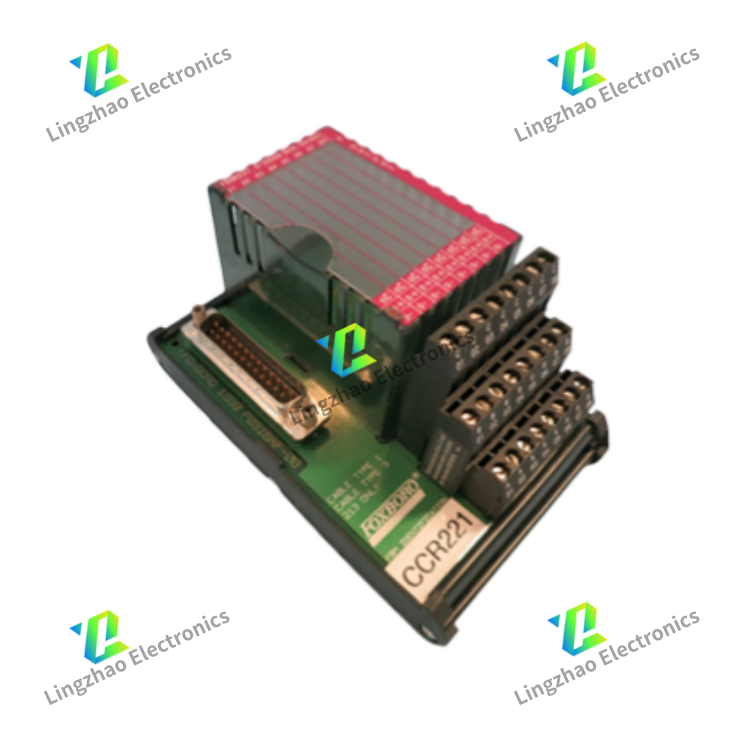

- Relay Outputs: 2 Form-C relays (1 normally open, 1 normally closed) – rated 250 V AC / 5 A, 30 V DC / 5 A. Each relay can be mapped to either channel’s alarm status (e.g., Relay 1 = Channel 1 Danger, Relay 2 = Channel 2 Danger) for direct control of external equipment (e.g., motor contactors, alarm buzzers).

- Analog Outputs: 2 configurable 4–20 mA analog outputs (1 per channel) – transmits real-time vibration amplitude data (e.g., 4 mA = 0 mm/s, 20 mA = 50 mm/s) to recorders, HMIs, or DCS systems for trend monitoring.

- Backplane Communication: Connects to the 3500 frame backplane – transmits raw vibration data, alarm status, and module health information to the 3500/92 communication gateway (for upper-level system integration).

- Configuration Methods:

- Local Configuration: Via the 3500 frame’s front-panel display (3500/05 frame) or a connected laptop (using Bently Nevada’s "3500 Configuration Software") – adjusts thresholds, filters, and output mappings without module removal.

- Remote Configuration: Via upper-level software (e.g., Bently System 1, DCS) through the 3500/92 gateway – supports batch configuration of multiple 3500/40 modules in large-scale systems (e.g., a factory with 20+ motor monitoring points).

- Self-Diagnosis: Monitors internal hardware (power supply, ADC circuits, relay contacts) and sensor connections (open-circuit, short-circuit detection) – triggers a "Module Fault" alert if anomalies are detected (e.g., sensor cable breakage), enabling proactive maintenance.

- Event Logging: Stores up to 500 historical alarm events per channel, including timestamp (millisecond precision), alarm type (Alert/Danger), and vibration amplitude at alarm trigger – supports post-fault root-cause analysis (e.g., identifying whether vibration spikes were caused by load changes or component failure).

- Waveform Capture: Optional raw waveform recording (1–10 seconds per capture) – triggered manually or automatically by danger alarms, capturing transient vibration signals (e.g., gearbox failure shocks) for detailed frequency analysis via Bently System 1 software.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

3500/15-05-05-00

3500/44m 126599-01

3500/92

3500/40 176449-01

3500/42M 140734-02

Product

Product Bently

Bently

Online Consultation

Online Consultation 13328303947

13328303947