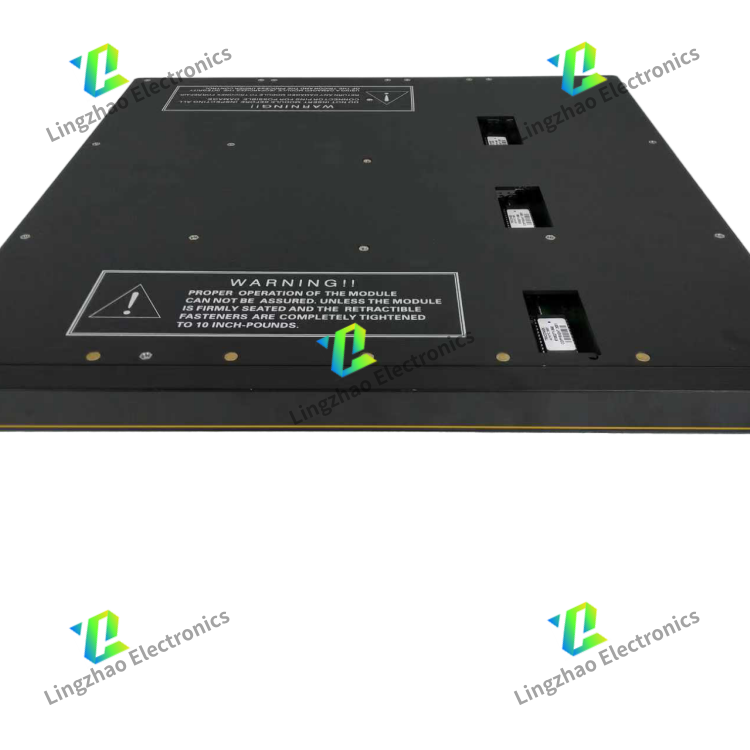

5SHX1060H0003 Insulated Gate Bipolar Transistor (IGBT) Module

5SHX1060H0003 is a high-performance Insulated Gate Bipolar Transistor (IGBT) Module developed by ABB, specifically designed for medium-power industrial power conversion scenarios. It integrates advanced semiconductor technology and robust structural design, balancing efficiency, reliability, and compactness—making it suitable for industrial drives, inverters, and power control systems that demand stable operation and energy savings. The detailed information is as follows:

- Rated Voltage (Collector-Emitter Voltage, V₍CE₎ₙₒₘ₋ₘₐₓ₎:

1200V DC (a common medium-voltage rating for industrial applications, compatible with 380V/480V AC grid systems, meeting the voltage requirements of most low-to-medium voltage industrial equipment such as motors and inverters). - Rated Current (Continuous Collector Current, I₍C₎ₙₒₘ₋ₐₘ₈₅ₒC₎:

600A (continuous operating current under standard ambient temperature (85°C) and proper cooling; peak surge current (I₍Cₚₖ₋ₘₐₓ₎) reaches up to 1200A for short durations (≤10ms), adapting to transient load peaks (e.g., motor startup or sudden load changes)). - Power Dissipation (Maximum, P₍ₗₒₛₛ₎ₘₐₓ₎:

Approximately 3.2kW (varies with switching frequency and junction temperature; requires a matched cooling solution—such as forced-air cooled heatsinks (for low-power scenarios) or water-cooled heatsinks (for high-power scenarios)—to maintain thermal balance and avoid overheating). - Switching Characteristics:

- Turn-on time (tₒₙ): ~0.5μs; Turn-off time (tₒₓₜ): ~0.8μs (fast switching speed, optimized for medium-frequency applications (2kHz–20kHz), reducing switching losses while ensuring stable commutation).

- Switching losses (Eₒₙ/Eₒₓₜ): ~15mJ/22mJ (at rated voltage and current, minimizing energy waste during on/off transitions, enabling overall system efficiency of 97%+ in inverter applications).

- Gate Drive Requirements:

- Gate voltage range: +15V (turn-on) / -10V (turn-off) (standard IGBT drive voltage, ensuring reliable switching and preventing false triggering caused by electromagnetic interference (EMI)).

- Gate current (peak): 20A–30A (sufficient drive current to ensure fast, complete switching of high-current IGBT chips, avoiding switching delay or incomplete turn-on/off losses).

- Anti-Parallel Freewheeling Diode (FWD):

Integrated high-speed FWD with reverse recovery time (tᵣᵣ) ≤45ns, reducing reverse recovery losses and suppressing voltage spikes during current commutation, thus enhancing the stability and lifespan of the power conversion system.

- Advanced Trench-Gate Chip Technology:

Adopts ABB’s Trench-Gate Field-Stop (TFS) IGBT chip design, which minimizes on-resistance (R₍CE₎ₒₙ ~2.5mΩ at rated current) to reduce conduction losses. The chip’s optimized structure also improves voltage withstand capability and anti-surge performance, making it suitable for harsh industrial grid conditions (e.g., voltage fluctuations, harmonics). - High Power Density & Compact Design:

Through integrated packaging and miniaturized chip layout, the module delivers a 600A/1200V rating in a small form factor, reducing the installation space of power cabinets by ~15% compared to traditional modules—facilitating system integration and miniaturization for equipment with space constraints. - Comprehensive Protection Mechanisms:

- Overtemperature Protection (OTP): Built-in NTC (Negative Temperature Coefficient) thermistor to real-time monitor the junction temperature (Tⱼ); triggers an alarm or emergency shutdown when Tⱼ exceeds 150°C, preventing chip burnout due to overheating.

- Overcurrent Protection (OCP): Compatible with external current sensors (e.g., Hall-effect sensors or shunts) for fast overcurrent response (≤1μs), shielding the module from damage caused by short circuits, load overloads, or grid faults.

- Undervoltage Lockout (UVLO): Disables switching if the gate drive voltage drops below 12V (turn-on) or rises above -8V (turn-off), avoiding abnormal operation or module damage due to insufficient drive power.

- Enhanced Environmental Adaptability:

- Isolation Voltage: ≥2500V AC (1 minute, between power terminals and baseplate), complying with IEC 60664 safety standards for industrial insulation—suitable for harsh environments with strict insulation requirements (e.g., dusty factories, high-humidity areas).

- Moisture & Dust Resistance: Uses hermetic ceramic-metal sealing technology to resist moisture (5%–95% RH, non-condensing) and dust, ensuring stable operation in industrial sites such as manufacturing plants, mines, or renewable energy farms.

- Operating Temperature Range:

- Junction temperature (Tⱼ): -40°C to +150°C (long-term operation is recommended at Tⱼ ≤125°C to extend the module’s service life to 100,000+ hours).

- Ambient temperature (Tₐ): -25°C to +85°C (auxiliary cooling is required if Tₐ exceeds 60°C to maintain rated current and voltage performance).

- Vibration & Shock Resistance:

- Vibration: 5g (10Hz–2000Hz, IEC 60068-2-6 standard), adapting to mechanical vibrations in motor drive cabinets or mobile industrial equipment (e.g., mining machinery, mobile generators).

- Shock: 30g (11ms, half-sine wave, IEC 60068-2-27 standard), withstanding short-term impact during transportation, installation, or equipment maintenance.

- Storage Conditions:

Temperature: -40°C to +85°C; Humidity: ≤85% RH (store in a dry, dust-free environment with anti-corrosion packaging to prevent terminal oxidation, insulation degradation, or chip moisture damage).

- Industrial AC Drives: Used in medium-to-high power motor speed control systems (e.g., 300kW–1000kW pumps, fans, conveyors, or compressors in manufacturing, mining, or water treatment industries) to achieve precise speed regulation and energy savings.

- Low-Medium Voltage Inverters: Applied in grid-connected inverters for small-to-medium renewable energy systems (e.g., 200kW–600kW solar PV inverters, small wind turbines) or industrial frequency converters for process control.

- Uninterruptible Power Supplies (UPS): Suitable for medium-power UPS systems (100kVA–300kVA) in commercial buildings, data centers, or industrial auxiliary loads, ensuring continuous power supply during grid outages.

- Welding & Induction Heating Equipment: Used in high-power welding machines (e.g., arc welding, laser welding) and medium-frequency induction heating systems (e.g., metal heat treatment, plastic molding), leveraging its fast switching and high current handling capabilities.

- Power Quality Equipment: Applied in low-voltage Active Power Filters (APF) or small Static Var Compensators (SVC) to suppress harmonic distortion and improve grid power quality for industrial workshops or commercial complexes.

The company has multiple main brands, and if you have other brand requirements, you can also send them to customer service for inquiry.

Related models:

Product

Product ABB

ABB

Online Consultation

Online Consultation 13328303947

13328303947